Ultimate Guide to Metal Fabrication & Optimizing Etchant for Stainless Steel 304

In today's industrial landscape, metal fabrication stands as a cornerstone of manufacturing, construction, and architectural excellence. With increasing demand for durable, aesthetically appealing, and precisely engineered stainless steel components, understanding the nuances of metal fabrication processes and selecting the right materials and chemicals is more critical than ever. At the forefront of this field is GoldeCo Steel, a trusted name among metal fabricators committed to delivering high-quality solutions tailored to diverse industry needs.

Understanding Metal Fabrication: The Foundation of Steel Engineering

Metal fabrication involves transforming raw metal materials into usable components and structures through a series of specialized processes. This encompasses cutting, bending, welding, grinding, and finishing, each requiring precision and expert knowledge to ensure the final product meets specifications, safety standards, and aesthetic expectations.

Key Processes in Metal Fabrication

- Cutting: Utilizing techniques such as laser cutting, plasma cutting, and water jet cutting to achieve precise dimensions.

- Bending and Forming: Shaping metal sheets and profiles into desired angles and curves using press brakes and other equipment.

- Welding: Joining metal parts through methods like MIG, TIG, and arc welding for durable, seamless structures.

- Finishing: Surface treatments including polishing, grinding, and coating to enhance appearance and corrosion resistance.

Each step demands exacting standards, especially when working with stainless steel, to preserve its integrity and functional properties.

Why GoldeCo Steel Leads in Metal Fabrication

As a premier metal fabricator, GoldeCo Steel specializes in delivering bespoke solutions that blend advanced technology with meticulous craftsmanship. Our extensive experience in handling various metals, especially stainless steel, positions us as industry leaders committed to excellence.

Our core strengths include:

- Advanced Equipment: Utilizing state-of-the-art machinery like CNC plasma cutters, high-precision laser systems, and automated bending machines.

- Skilled Workforce: Employing highly trained professionals who possess deep technical knowledge and artistic sensibility.

- Quality Assurance: Implementing rigorous quality control protocols throughout the fabrication process.

- Customer-Centric Approach: Customizing solutions to meet specific project demands, deadlines, and budgets.

Exploring the Role of Etchants in Stainless Steel Fabrication

In the realm of metal fabrication, chemical treatments such as etching are invaluable for both functional and aesthetic purposes. Specifically, for stainless steel 304, selecting an appropriate etchant for stainless steel 304 can improve surface quality, reveal intricate designs, or prepare surfaces for further finishing.

What is Etching and How Does it Work?

Etching is a controlled chemical process that involves applying a solution to the metal surface to remove a thin layer, creating patterns, textures, or preparing surfaces for coating or welding. The process offers high precision and the ability to produce detailed designs that mechanical processes might struggle to achieve.

Benefits of Using Etchant for Stainless Steel 304

- Aesthetic Customization: Creating decorative patterns, logos, or surface textures.

- Surface Preparation: Improving adhesion for coatings, paints, or adhesives.

- Corrosion Resistance: Enhancing surface characteristics to improve durability.

- Material Conservation: Achieving desired effects without material wastage typical of abrasive methods.

Choosing the Best Etchant for Stainless Steel 304

While numerous chemical solutions are available, selecting the optimal etchant for stainless steel 304 depends on factors such as desired pattern detail, surface finish, safety considerations, and environmental impact.

Common Chemicals Used as Etchants for Stainless Steel 304

- Citric Acid: A safer, environmentally friendly option, producing a subtle matte finish ideal for decorative applications.

- Ferric Chloride: Widely used in PCB etching, providing fast and clean results for detailed patterns.

- Nitric Acid and Hydrochloric Acid Mixtures: Strong acids often used for deep etching but require strict safety measures due to their corrosive nature.

- Phosphoric Acid: Suitable for surface cleaning and light etching, offering good control and safety.

Best Practices When Using Etchants on Stainless Steel 304

- Safety Precautions: Always wear protective gear, including gloves, goggles, and respirators, and work in well-ventilated areas.

- Surface Preparation: Clean the surface thoroughly to remove oils, dirt, and oxidation for uniform etching.

- Test Before Full Application: Conduct small-scale tests to determine optimal concentration and exposure time.

- Proper Disposal: Follow environmental regulations regarding chemical waste disposal.

- Post-Etching Treatment: Rinse and neutralize the surface to halt etching and prepare for further finishing.

Advanced Techniques and Innovations in Metal Fabrication

As industry standards evolve, modern metal fabricators like GoldeCo Steel incorporate innovative techniques to enhance efficiency, precision, and sustainability.

Laser Etching and Micro-etching

Utilizes high-powered lasers for detailed, controlled etching without chemical use, suitable for intricate designs on stainless steel 304. This method offers unmatched precision, repeatability, and environmental benefits.

Reactive Metal Printing and Chemical Etching

Integrating 3D printing with chemical etching allows for rapid prototyping and complex geometries, pushing the boundaries of traditional manufacturing.

Surface Treatment Technologies

In combination with etching, processes such as passivation and coating improve corrosion resistance and surface finish, extending the lifespan of fabricated components.

Industrial Applications of Etchant for Stainless Steel 304

The use of etchant for stainless steel 304 spans multiple sectors, such as:

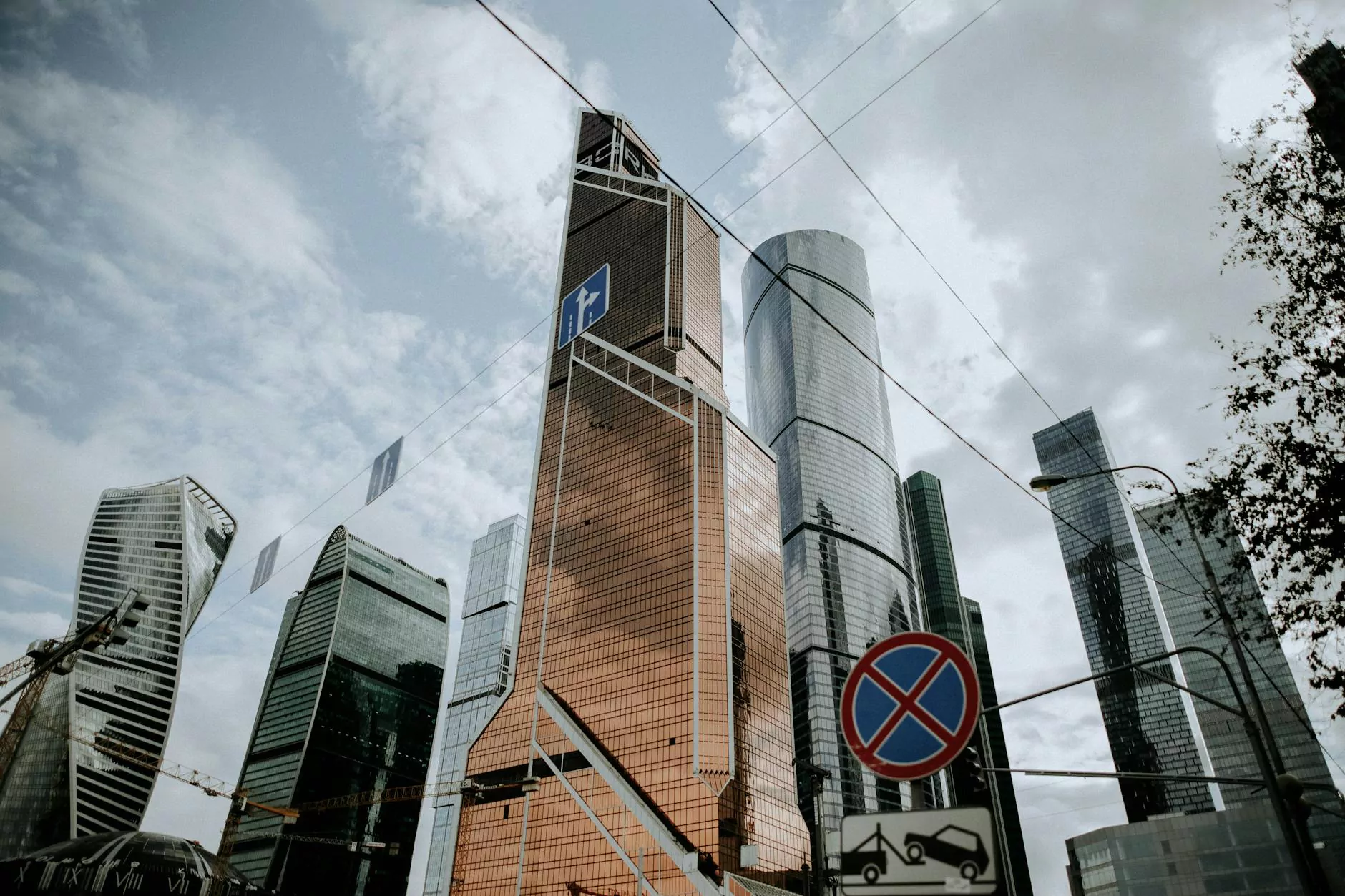

- Architectural Design: Creating artistic facades, decorative panels, and intricate railings.

- Medical Equipment: Preparing surfaces to improve sterilization and biocompatibility.

- Electronics and PCB Manufacturing: Patterning conductive pathways with ferric chloride etchants.

- Automotive and Aerospace: Enhancing component surfaces for better performance and corrosion resistance.

Why Quality in Metal Fabrication Matters

High-quality fabrication, coupled with the right chemical treatments, guarantees durability, aesthetic appeal, and functional reliability. Working with reputable providers like GoldeCo Steel ensures adherence to standards, innovation, and environmental responsibility in every project.

Conclusion: Elevate Your Metal Fabrication Projects with Expert Knowledge and Superior Materials

As we have explored, the meticulous selection of processes, chemicals, and techniques—especially choosing the correct etchant for stainless steel 304—can significantly impact the results of your projects. Whether you're aiming for artistic expression, technical precision, or enhanced corrosion resistance, integrating expert guidance and high-quality materials makes all the difference.

GoldeCo Steel remains committed to delivering excellence in metal fabrication, harnessing cutting-edge technology and industry best practices to serve clients' complex needs. Embrace innovation, prioritize quality, and achieve outstanding results that stand the test of time.

For further professional guidance or custom fabrication solutions, contact GoldeCo Steel today and elevate your metalworking projects to new heights.