Exploring the World of Injection Mold Tooling China

In the rapidly evolving landscape of manufacturing, injection mold tooling in China stands out as a beacon of efficiency and innovation. This process not only represents a key cornerstone of production in various industries, but it also highlights China's pivotal role in the global market for metal fabricators. By understanding the underlying principles and benefits of injection mold tooling, businesses can harness its potential to maximize efficiency and quality.

What is Injection Mold Tooling?

Injection mold tooling refers to a manufacturing process where molten material—usually plastic or metal—is injected into a mold cavity to create parts of various shapes and sizes. This process is fundamental in the production of intricate components used in automotive, consumer electronics, and other high-volume manufacturing sectors. However, the precision and finesse required in the tooling process are where China's expertise truly shines.

The Advantages of Choosing Chinese Tooling Manufacturers

Businesses often seek suppliers from China for various compelling reasons. Here are some notable advantages:

- Cost Efficiency: Chinese manufacturers can produce high-quality tooling at a fraction of the cost compared to Western counterparts. This is primarily due to lower labor costs and an efficient supply chain.

- Advanced Technology: Many manufacturers in China leverage state-of-the-art technology and equipment to produce precise molds. This ensures that the final products meet stringent quality standards.

- Rapid Production Turnaround: With streamlined processes in place, Chinese manufacturers are capable of delivering products faster, which is crucial for businesses looking to minimize time-to-market.

- Flexible Production Capabilities: Whether small batch runs or mass production, Chinese tooling manufacturers can scale their operations to meet varying demands.

The Injection Molding Process

1. Design and Prototyping

Before any physical molds can be created, the process begins with design and prototyping. This stage involves using computer-aided design (CAD) software to create detailed designs and simulations of the final part. Prototyping allows for adjustments and modifications before committing to production.

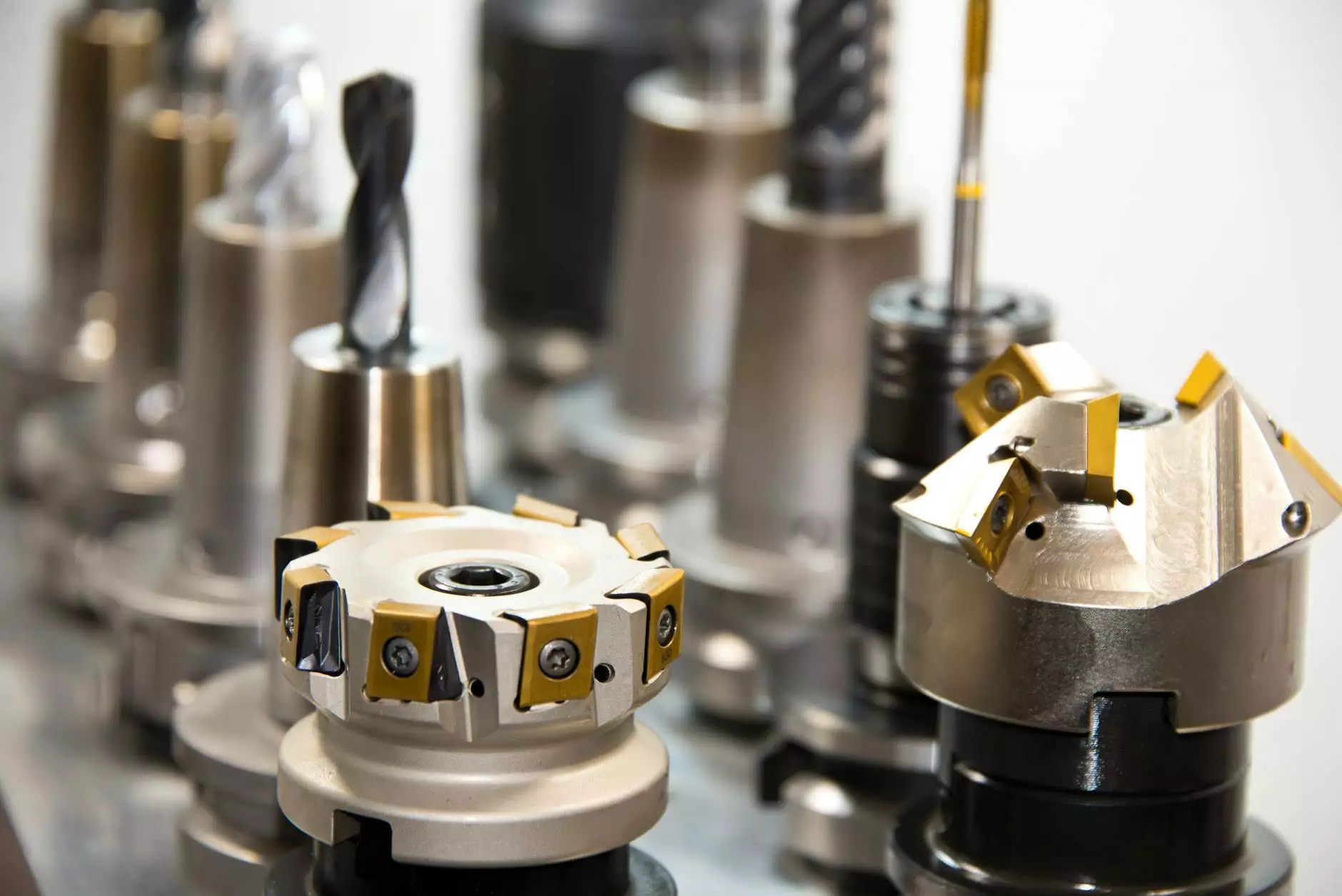

2. Mold Fabrication

Once the design is finalized, the next step is the fabrication of the mold. This is where injection mold tooling in China excels. High-quality steel or aluminum is used to create molds that can withstand the immense pressures of injection molding.

3. Injection Process

In this phase, the molten material is injected into the mold under high pressure. The process must be carefully controlled, as any discrepancies can lead to defects in the final product.

4. Cooling and Ejection

After the material has filled the mold, it is allowed to cool and solidify. The mold is then opened, and the finished part is ejected. This step requires precision to ensure that the part does not get damaged during ejection.

Quality Control in Injection Mold Tooling

Maintaining high-quality standards is essential in the injection mold tooling process. Quality control measures adopted by Chinese manufacturers include rigorous testing and inspection procedures at each step of the process. Common practices include:

- Material Inspection: Ensuring that raw materials meet specific criteria before they are used in production.

- Dimensional Inspection: Using advanced measurement tools to ensure the final parts adhere to design specifications.

- Functional Testing: Conducting tests on the molded parts to ensure they perform as intended in real-world applications.

Common Industries Using Injection Mold Tooling

Injection mold tooling in China serves a myriad of industries. Let's explore some of the most prominent sectors benefiting from this technology:

- Automotive: Injection molding is used extensively to produce components such as dashboards, panels, and casings.

- Consumer Electronics: The industry relies on precision-molded parts for devices like smartphones, tablets, and laptops.

- Medical Devices: Injection molded components are crucial for many medical products, including syringes and surgical instruments.

- Household Goods: From kitchenware to furniture, many consumer products are manufactured using injection molding techniques.

Trends and Innovations in Injection Mold Tooling

As technology advances, so does the field of injection mold tooling. Emerging trends include:

- 3D Printing for Tooling: Some manufacturers are integrating 3D printing technologies to produce molds rapidly and at lower costs.

- Smart Manufacturing: The adoption of IoT devices is enhancing monitoring and automation in injection molding processes.

- Use of Advanced Materials: Companies are increasingly exploring new materials such as bio-based plastics and innovative alloys for better performance.

Choosing the Right Injection Mold Tooling Partner

Selecting a supplier for your injection mold tooling needs is a critical decision. Here are key factors to consider:

- Experience: Look for manufacturers with a proven track record in the industry.

- Evaluating Capabilities: Verify whether the company can handle your specific project requirements, including materials and quantities.

- Communication: Strong communication channels are essential for effective project management and timely updates.

- Customer Support: Ensure they offer robust customer service to address any issues that may arise throughout the project lifecycle.

Conclusion

In conclusion, injection mold tooling in China represents not just a manufacturing technique but a vital component of modern production. Its advantages in terms of cost, speed, and technology make it an attractive option for businesses worldwide. By understanding the intricacies of this process, companies can better leverage these solutions to drive their operations and ensure high-quality outputs. Partnering with reliable manufacturers in China will undoubtedly enhance your competitive edge in the market.

Contact Us for More Information

If you're looking to explore options in injection mold tooling, feel free to reach out to us at deepmould.net. Our team is ready to assist you in finding the best solutions tailored to your business needs.

injection mold tooling china